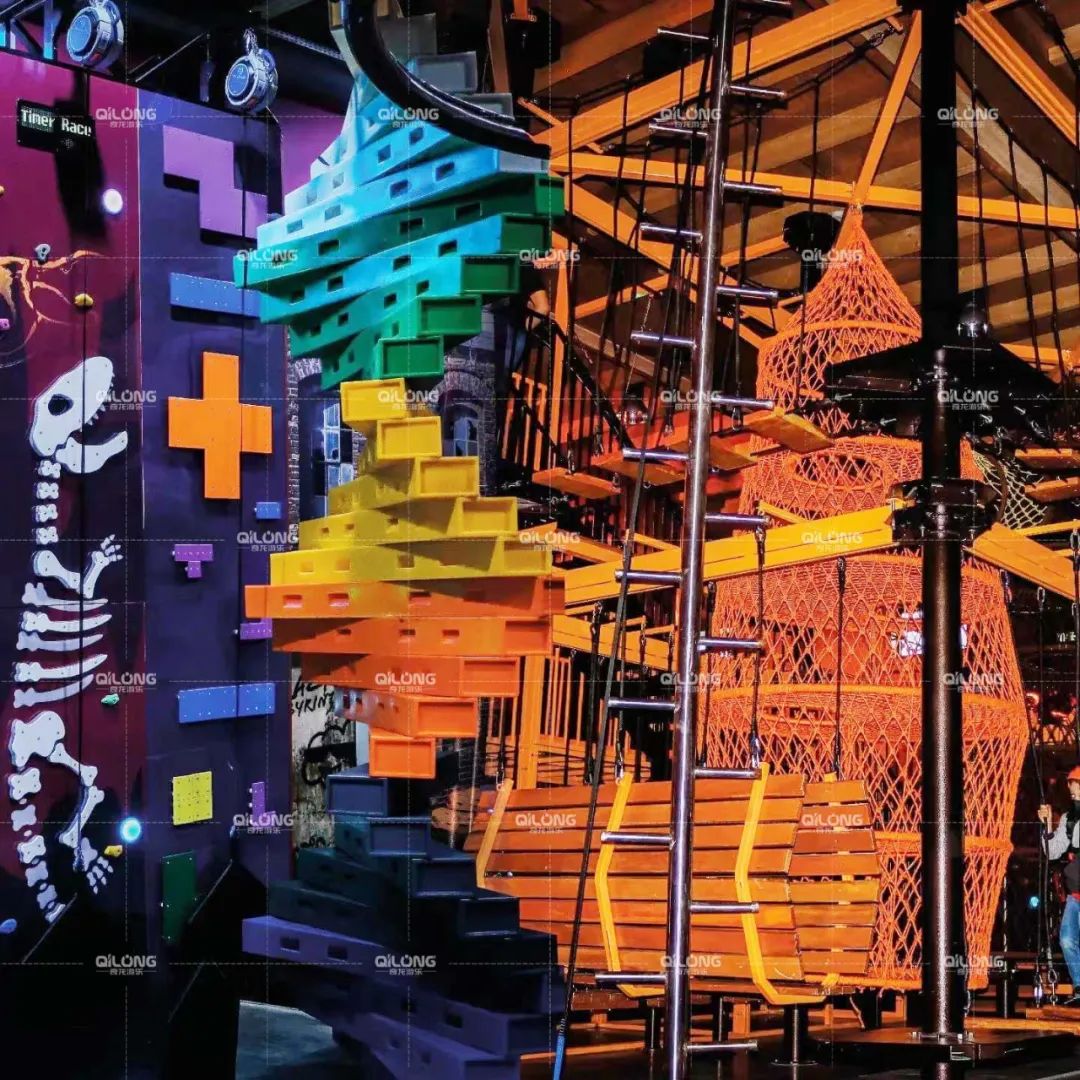

In the current environment, children's playground equipment is becoming more and more popular in the market.

Whether it is a park, a children's playground, or a shopping mall, there are children's expansion equipment.

Below, we shared with you about the playground equipment inspection, repair and maintenance methods tips.

A.Check on time

Check the structure of each part of the equipment once a week, if the screws are loose or damaged,

they should be removed and improved immediately before starting business.

B.Check key parts

Before each use, inspect all wear and loose parts of fasteners, wire ropes on corresponding rods,

wire rope clamps, pulley parts, wire rope turnbuckles, bow shackles.

When the wear of the safety equipment exceeds 1/10 of the original, it should be renewed:

If the wire rope has broken strands, the loose parts should be renewed,

tightened and locked when the number of broken strands exceeds 1/10 of the total number of strands of the wire rope.

Inspectors should wear seat belts and helmets during their work.

C.Anticorrosion treatment of metal parts

Columns and beams are subjected to anti-corrosion treatment every six months;

the welding parts of the wire rope lugs should be inspected once a month;

when the corrosion depth exceeds 1/10 of the steel pipe wall thickness,

it should be replaced. Before each workout, check the hoop of the horizontal bar to see if it moves freely on the beam.

If it is found that it is difficult to move, it should be lubricated in time.

D.Regular maintenance of solid parts

Climb at least every six months to secure all grab blocks and climbing boards.

Before each training session, someone must check the moves and the climbing board.

If there is any looseness, it must be tightened before training.

The connecting bolts behind the rock slabs must be tightened at least every six months.

Before each training, check whether the worm and worm gear for adjusting the width of the

broken bridge rotate freely within the specified stroke.

If it is found that it is difficult to rotate, grease should be applied in time.

E.Anticorrosion treatment

The edges and welds of all equipment should be treated with anti-corrosion treatment in spring and autumn every year,

and anti-corrosion treatment should be carried out in wet and rainy places before the rainy season.

All instruments are preservative every two years. During anti-corrosion treatment, the instrument must be polished

with 300-mesh gauze first, and then the primer and topcoat must be brushed twice.

More skills are all in Qilong, contact me now!